January 29, 2019

For the past 10 years, ONA Consultants has developed and engineered ship to ship mooring procedures, gaining a nuanced understanding of their complexities and challenges. Our experience includes many barge to construction vessel scenarios, deep sea mooring to offtake bulk carriers on higher sea states, and in some cases -assessment of the use of DP vessel functions conjunctly with ship to ship moorings.

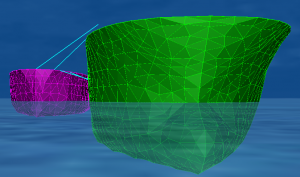

Strapping two ships together with different motion characteristics and expecting them to behave in unison requires the motion characteristics of each to be established, then coupled like any multibody analysis. More recently, with the advent of mega ships and facilities such as Prelude, much focus is on the hydrodynamic interaction between the tow vessels. The bigger the ship, the higher the inertia and the greater the interactive hydrodynamic influence on each other. Accordingly, these projects attract significant funding from innovative, risk adverse companies thereby driving analytical pursuits in institutions worldwide.

There is a pool of experienced mariners who have piloted and coordinated tanker to tanker offtakes for years. Some of the first commercial ship to ship lightering operations were undertaken at Port Stanvac, South Australia between 54,000 and 26,000DWT Product Carriers. Thereafter larger crude carriers were involved in ship to ship transfers, reportedly by Exxon Mobil.

The major difference is the sea states envisaged for such operations are significantly higher and the consequences of collision are much higher. The effect of hydraulic interaction between vessels starts to play a larger, more significant role in motions and loads.

To put this in perspective, you only need to witness FPSO offtake tanker operations to understand the subtleties and finesse required by pilots and mariners’ when large ships are in close proximity. Many companies and consultants specialise in such ship to ship transfer operations. The uptake of LNG export and LNG bunkering operations will see a proliferation of ship to ship mooring operations at all scales at least until shoreside infrastructure catches up.

In the work we have done at ONA there were always two distinctly different problems. One is to analyse the vessels while moored together, and the other is to try and get the vessels moored together. Analytically, regardless of the interactive influences between the vessels, it is possible to analyse in time domain and post process the forces in mooring lines. In a similar way to ship to shore moorings (benign), it becomes clear that short lines cannot be readily used to hold the relative surge between vessels. Therefore, the use of stretchers and surge compensation devices is paramount. While easy to model numerically, the practical consequences of allowing a mooring line to change shape and stretch necessitates careful design of fittings to avoid hard edges particularly for synthetics. Other similarities include adequately modelling realistic pre-tensions in lines. Ship to ship mooring lines do require careful monitoring and management of line tensions well beyond shore mooring operations to avoid overloading, under loading and snatch loading.

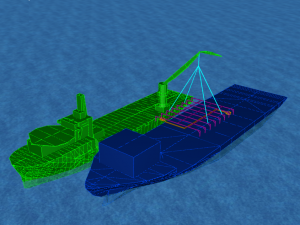

The second area of analysis that is important, but most difficult to model and analyse is the initial mooring hookup stages. Ship mooring lines are typically connected while a vessel is held independently in place alongside a wharf until tensioning of mooring lines can be coordinated. Offshore, in ship to ship operations, the practitioners must manage the uptake of tension on each mooring line until coupling of the vessels is complete. Often this requires a strategy of leaning on mooring lines and the use of assist tugs which further complicate control scenarios. Suddenly there is a multitude of scenarios and design load cases that must be identified, rationalized and assessed. This is where any analysis strategy must be closely coordinated with parallel ship simulation so that control inputs, human intervention and engineering implications can be refined. In years gone past this was the domain of the experienced mariner who’s judgement and experience were well tempered and if they were really fortunate, reputations remained intact. We have been fortunate to work with quite a few whose input into operational scenarios was instrumental in shaping the mooring hook up philosophies and parring down the mooring load cases to be used. Some operational analysis has included consideration of mooring winches operating in constant tension mode which need to be analysed and engineered properly.

In assessing ship to ship moorings, by far the biggest influence is the use of ship simulators to provide the human element in control situations and assist bound the engineering load cases. We also recommend clients seriously consider a layered analytical and simulation approach to assessing and planning ship to ship operations. Most importantly, ship to ship moorings, like all moorings require tending and no single mooring setup load case is adequate for all operations and environmental conditions if any sort of real operability level is sought.

ONA is well placed to support campaigns and projects in exploring vessel mooring capacity, motions and the safe operability. We have management experience in both engineering and the use of tailored simulation in achieving safe operational outcomes.