August 15, 2017

The following Insight from Jordan Rayson, Offshore Engineer, explores the integrity assessment of gravity anchors:

Gravity-based anchors remain an acceptable anchoring method in mooring systems around the world. There are two prominent types of gravity-based anchors: steel and concrete. Both rely on keying into the seafloor and the use of ballast or overburden to enhance holding power. Assessing the integrity of gravity anchors, particularly the steel type, comes with unique challenges. This requires a comprehensive knowledge of moorings, foundations and corrosion. This article offers insights into the approaches used during a re-lifing assessment.

Identifying the original design capacity

Our approach typically begins with a desktop review of the entire mooring system, which starts with understanding the original design intent. We begin by reviewing the design calculations to understand and frame up the design assumptions. If the design calculations have not been kept, which may be the case for a lot of older anchors, we carry out our own calculations based on the design, albeit using more current assessment approaches.

Designing for the available anchor capacity is challenging. Often, this is attributed to a poor basis of design due to a lack of available metocean data driving mooring line loads or the absence of robust seafloor soil information. This can be particularly challenging for projects on the North West Shelf, where the location and nature of calcareous layers is inconsistent. Designers typically try to account for such variabilities through design conservatism, in accordance with good design practice.

Historical installation and inspection background

Next, we conduct a review of the available as-built information and historical inspection records. From this we can evaluate how effective the design was and how closely the as-installed anchor met the designer’s intent. Quite often there remains traceable Classification Society approval driving the recorded installation information.

In more prudent design work, there is usually evidence of a final review of the design cycle, post installation. The availability and quality of this background forms the basis for the specification of future subsea inspection work required for asset management and re-lifing.

Establishing the required design capacity

Historically, we’ve found it prudent to check the requirements for the field, or location, remain valid as consideration for re-lifing assessments. Therefore, we review the operational profile of the mooring system, including consideration of changes in the environmental return periods and the effect of these return periods on hydrocarbon risk considerations.

For example, over the past 20 years, the 10-year design wave return period on the North West Shelf has increased considerably, so this must be taken into account, along with the effect on the hydrocarbon transfer systems that rely on the integrity of the mooring system, influencing re-lifing strategies.

Subsea inspection campaign

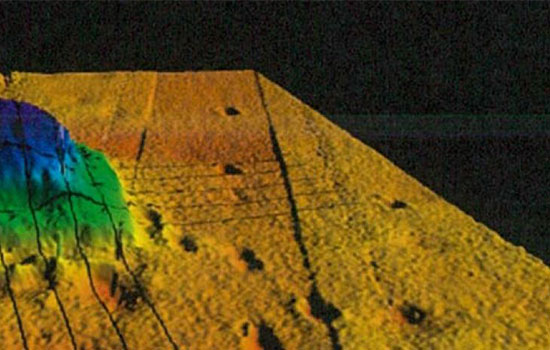

Depending on complexity, subsea inspection campaigns can be costly at AU$1-$3 million per campaign. During the course of a campaign, it’s likely additional specific subsea inspections are required. Scopes include the need for subsea surveys, bathymetry, thickness testing, cathodic protection checks and visual inspections that may require ROV and side scans capabilities. This can be achieved in a one-off diverless campaign, or specific scopes can be integrated into other existing programmed campaigns within the re-lifing schedule.

Information review

Armed with a cache of information, we assess the integrity of gravity anchors, with specific consideration of potential failure mechanisms, including:

- Structural integrity of the main or connecting components compromised through corrosion or wastage (steel).

- Structural degradation due to spalling (concrete).

- Loss of capacity due to disturbance of the seabed, such as scouring, excessive settlement or overburden.

- Loss of capacity due to an event causing re-orientation of the structure and associated seabed surrounds due to twisting or uplift.

It is also important to assess and establish whether the anchor or anchors in the system have dragged significantly. Based on the available client-provided historical analysis and data, it’s sometimes possible to identify particular cyclonic events that gave rise to the likely extreme anchor loads that may have caused movement – this assists in benchmarking the information. We therefore have the benefit of hindsight, which can then be used to formulate mitigations, as required.

Completing the puzzle

At the completion of the process, we’re able to determine, with some level of confidence, whether the anchor has a usable life ahead, should be replaced or, as is often the case, should be monitored further. Our role is to provide some justifiable conclusions to our clients based on what can often appear like a jigsaw puzzle with missing pieces.

The key, in our view, is working collaboratively with our clients to formulate re-lifing conclusions, providing the full benefit of our extensive service capabilities, which include ongoing inspection, maintenance, repair and replacement (IMR) strategies.

Tap into our expertise